Swapping out an overheating decoder for a Bachmann WD Austerity

The WD became an integral part of the Hall Royd scene from the early 1950s through to the extinction of the class in the fall of 1967. They originally reached Hall Royd from Sowerby Bridge shed, when they were deployed on banking duties as well as the mineral hauls from Healey Mills to Rose Grove, and also to Manchester. One of Richard Greenwood's film clips shows a WD slogging it through Hall Royd with a consignment of loco coal for Edge Hill shed.

When the conversion programme for fitting DCC decoders got underway in 2012, a WD was high on the list. These models are not DCC friendly as there is a large weight forming an integral part of the boiler, and there is no room for a DCC socket. As the WD was the first loco to be hard wired, extensive Web search was undertaken to find step-by-step instructions.

The conversion was a success and the locomotive with its Lenz decoder performed faultlessly for four and half years. Then it started shorting. It would run absolutely fine for about 5 minutes and then a mysterious short would occur. Remove the loco from the track and the short was also removed.

After a couple of such occurrences, the loco was completely stripped down, with the wheels and pick-ups removed, and then carefully reassembled, with the electrical integrity being tested as each element was replaced. Not surprisingly, the loco checked out as 100% electrically wired with no sign of a short. Placed back on the track it ran for 5 minutes before the short reoccured.

Finally the problem was shared with the DCC Model Railways group on Facebook. I am very grateful to Peter Mcgee who suggested that the problem sounded like the decoder suffering from some kind of 'internal heat fatigue'. His suggestion was to swap out the existing decoder to see whether this was the route of the problem. The following images provide a blow-by-blow account.

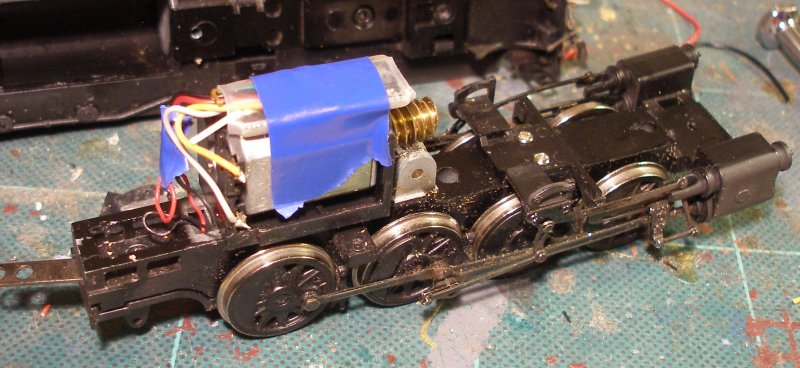

First, here is the loco sitting on the work bench. For those interested in such things, according to the BR Database 90015 was a New England loco withdrawn in 1963 so a new number may also be required.

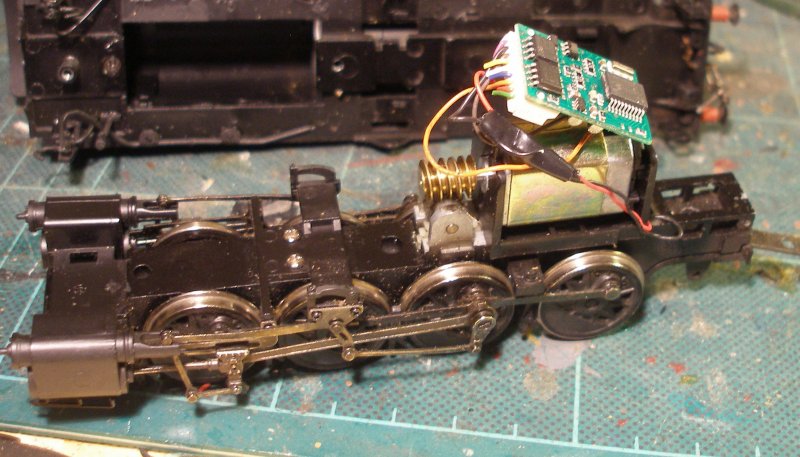

There are three screws holding the body on: one under the pony truck, one in the middle of the keeper plate and one under the brake gear actuating am under the cab. This view shows how the original Lenz chip was fitted on top of the motor and protected by black insulation tape. Note the tight space inside the firebox.

With the tape removed, it is possible to see how the decoder is wired in, with the greay and orange wires soldered directly to the bri=ushes on the motor, and the red and black wired directly to the corresponding wires from the pick-ups (the bare bits being carefully covered in insulation tape).

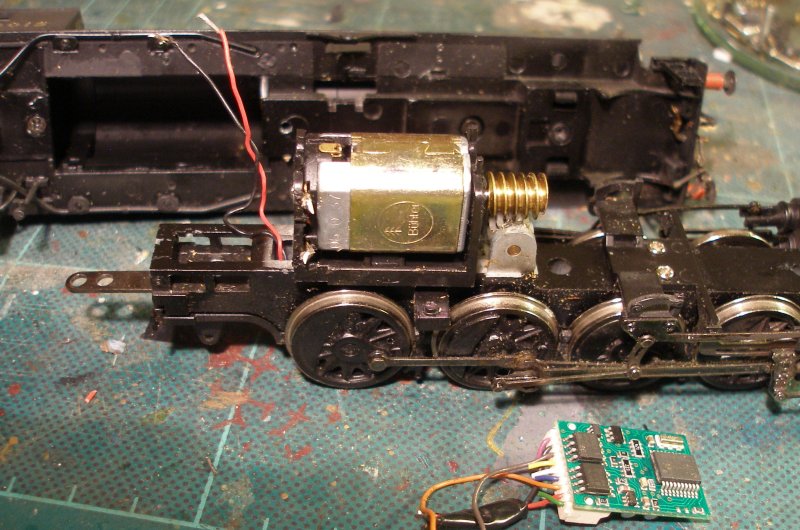

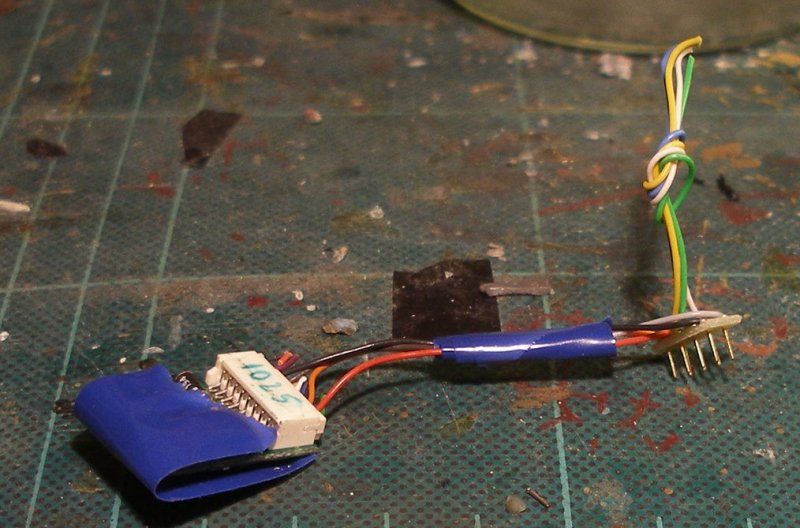

And now with the Lenz 1025 decoder removed (shows as '99' using the NMRA Manufacturers table, and '54' in the decoder type).

The new decoder is the Zimo budget MX600R. The harness has been cut off in this view, and the red and black, and grey and orange wires soldered in place.

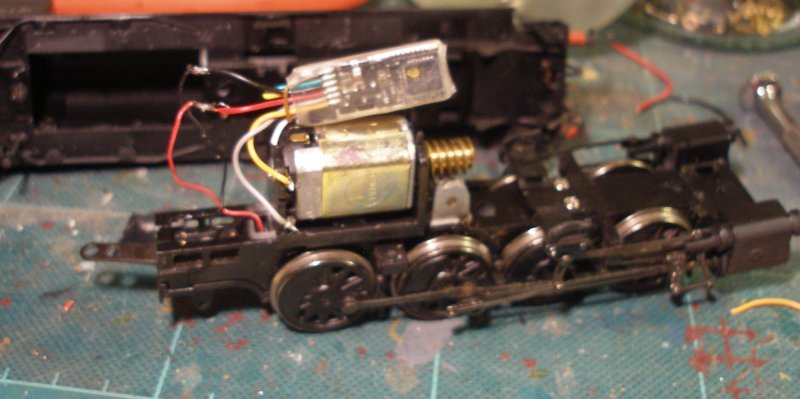

Insulation tape is applied to the red and black wires where there is bare metal, and the decoder is lightly taped to the top of the motor. The decoder comes ready fitted with a protective sleeve.

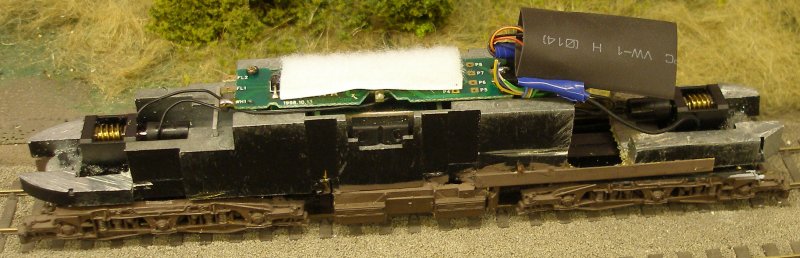

And to complete the sequence, here is the loco with the body back on, and the Lenz decoder in the foreground.

Finally, a test run was required, and here is 90015 passing Hall Royd Junction for about the tenth time as it is tested.

The interesting thing about the Lenz decoder was that left for about 24 hours it could recover, and therefore it was worth testing in a different environment. Consequently the plug recovered from the Zimo was attached.

Steve Angell on the DCC Facebook group also noted that the traditional black insulation tape is very poor heat sink, so using it will exacerbate overheating. It is worth noting that decoders should have a sleeve or cover of some sort as they are susceptible to handling with fingers, and must not touch any live metal surfaces when installed (I didn't get to where I am today without blowing a few decoders along the way!).

However it is good advice, and a spare Hornby insulated sleeve was to hand. The Lenz decoder now has a new home, namely a Class 47 with plenty of room to breathe, and so far is working perfectly.

25 October 2017