Upgrading the Hornby Class 110

The 3-car BRCW Class 110 diesel multiple units were synonymous with the Calder Valley. They were a development of the earlier Class 104, and some simple design tweeks produced a very nice looking train: better looking than the average cross-country DMU but not quiet in the same class, so to speak, as the Class 124 Trans-Pennine units. They were fitted with extra engines to allow them to tackle the gradients of the ex-LYR main line, which they did with some aplomb.

If you want one of these, the only unit available is the Hornby one, which was originally made in the UK, and then had a modest upgrade when production shifted to China.

The Achilles heal of these models are the bogies.

Hornby hit on the idea of lowering the centre of gravity so that the bogies swiveled in a pocket created at frame level, rather than a pivot located somewhere in the roof space. This neat piece of engineering allowed the same bogie frame molding to be used for all three types of bogie.

The plain bogies are not particularly free running, and they also have relatively little freedom to rotate side-to-side or fore-and-aft, and so are more prone to derailing.

The motor bogie can also suffer from rotational issues. Hornby fitted these units with traction tyres, which were one side, leaving the other pair of wheels to pick up current from one rail.

The other bogie on the power car had a live inner metal frame which then picked up current from the other rail. This bogie doesn't run particularly freely.

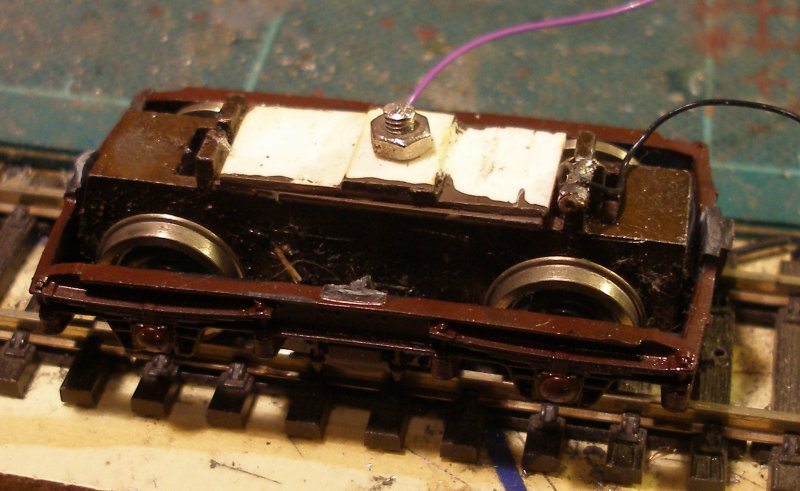

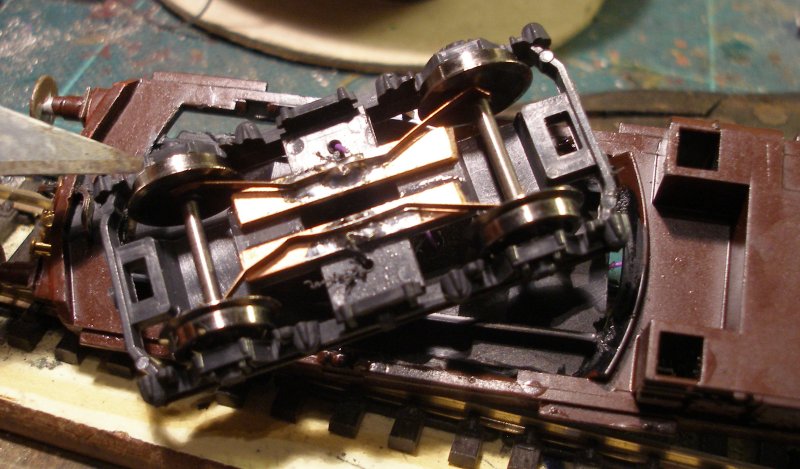

The photo below shows a bogie that has been modified to provide a centre spigot which was inserted through the original cross beam. The arms at either end and in the centre of the frames which originally located the bogie in the frame pocket have been removed.

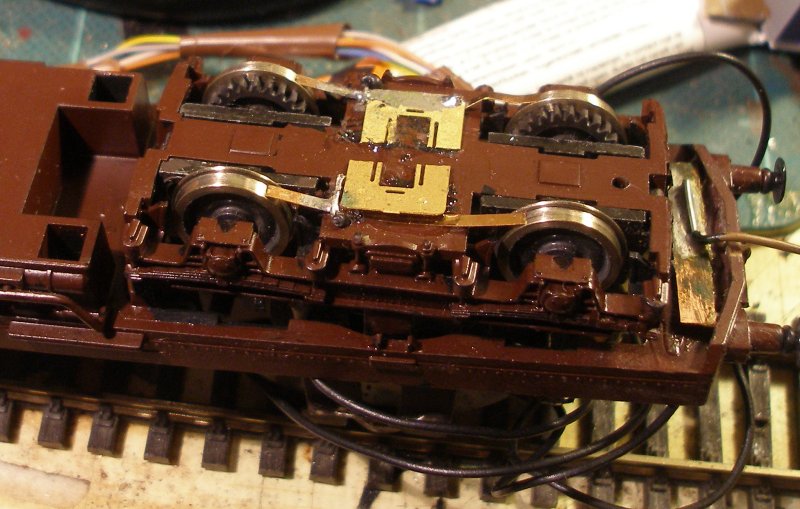

This photo shows the inner metal frame extracted from the plastic outer frame. This has been upgrade with a set of Ultrascale wheels, which just drop in. These preserve the original pick-up arrangements, with power being picked-up on one side.

This shows that flip side on the inner metal frame.

It might be wondered why a three car train needs traction tyres fitting, and the suspicion is that the train is not particularly free running, and the traction tyres are something of a fudge.

By contrast, LIMA produced a number of DMUs which had some particularly free running bogies. Unfortunately LIMA adopted a very crude wheel flange, much deeper than anything else on the market recently, and more akin to the original Tri-ang wheels of old. Upgrading to more modern wheels has always been a problem as LIMA adopted a shorter axle than found on Hornby or Bachmann models. This means that LIMA bogies cannot be used for EM or P4 models. Fortunately for OO modellers, Peter's Spares offer replacement wheel sets.

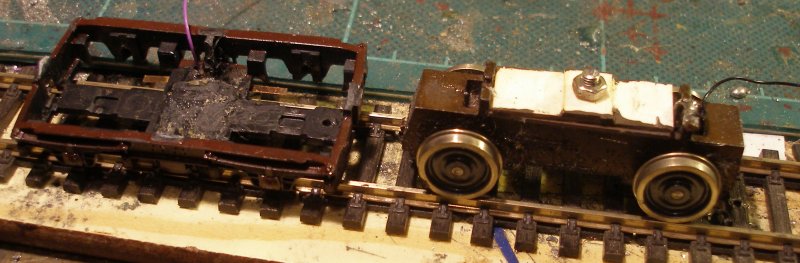

There are a number of ways these bogies can be attached to the Hornby chassis. In this example, a section from the donor LIMA chassis has been cut out, shaped and then glued into the pocket. The cross beam has been had the under edge pared down until the correct ride height was obtained. Note the pair of pick-up wires fed through from the underside of the bogie.

As this bogie is on the power car, it needed pick-ups. On the LIMA bogie, these are very easy to fit. Two pieces of copper Paxolin have been glued to the underside of the bogie. Slater's copper was then cut to length and bent to shape, before being soldered to the Paxolin strip. Finally thin wire was fed through holes drilled through the bogie and frame section and also soldered to the Paxolin. This arrangement runs more freely than the Hornby original, despite the pick-ups bearing on the backs of the wheels.

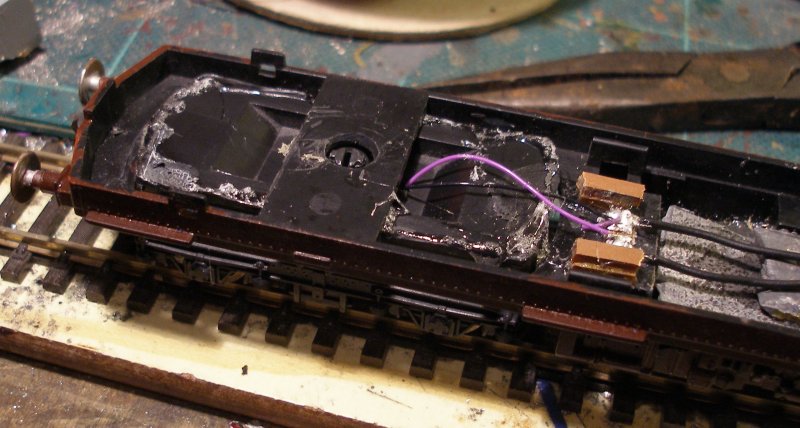

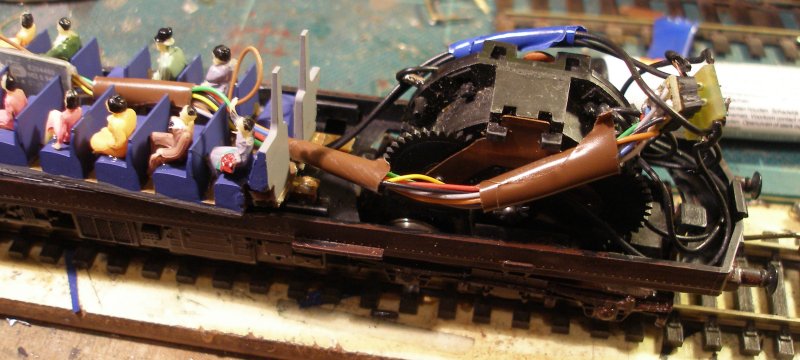

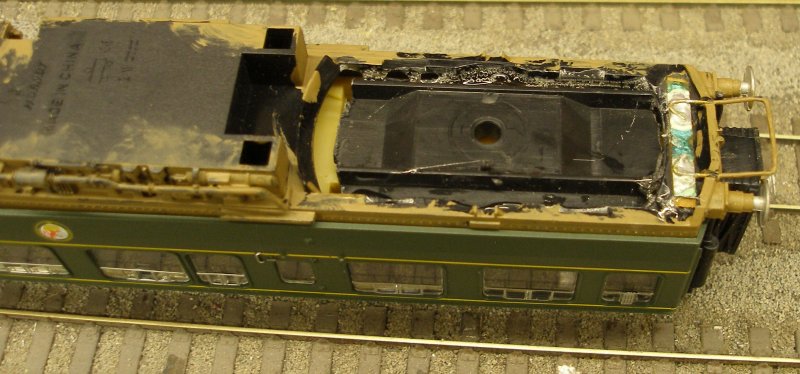

The power bogie also needs enhanced pick-ups, but the arrangement of cogs and the design of the plastic outer frame precludes fitting the enhanced pick-ups inside the frame. This photo shows a solution that provides pick-ups on both sides. Technically only one set is required, but the intention is that the set on the live side will clean the wheel tread.

It proved possible to fit a DCC socket, so allowing the Zimo MX600R decoder to be plugged in.

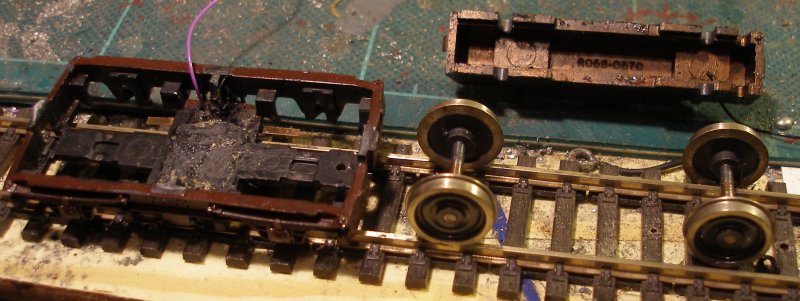

The Hornby design features two types of bogie pocket, with one allowing a motor bogie to be fitted. This means that different techniques are required for the two types.

The left hand side shows the cross-bar fitted for the plain, non-motored bogie. It is possible to build-up the depth of the cross-member until the correct bogie ride height is obtained. A hole is then drilled in the centre to take the LIMA retaining clip.

The other end does not have a handy cross-bar, and the original LIMA donor frame has been cut to create a section that simply drops into the pocket and then glued into place. These are shown in greater detail below.

And with the LIMA bogie attached...