<<< Fried sound chips Construction of a work bench >>>

The Sharge UK Track Cleaner

I am coming round to the idea that DCC is a 'good thing' but there are some downers, and in particular clean wheels and tracks are critical for good running.

I have a theory that the reason that running is so erratic in DCC with dirty wheels is that the chip loses the connection with the command station. Imagine using the TV remote to change channels, and that you are changing up a channel every two seconds by pressing the 'channel up' button. Then a friend stands between you and the TV. You continue to press the button every two seconds but the TV remains on the last channel selected before your friend stood in front on it. Your friend moves away, and assuming you are still pressing the button, the channels start changing again.

Now if we assume the crud on the rail has taken the place of your friend, then we have a similar situation. The loco is running on full throttle, and when it hits the crud, the command signal is interrupted but NOT the traction current. This results in the loco heading at full speed towards the buffer stop, but the command for speed reduction is not received, hence why locos appear to be unresponsive or erratic: either they wont start or wont stop!

Whether I'm right or not, there is no doubt that with DCC, there needs to be a cleaning routine as part of the regular layout maintenance which is carried out weekly and across the fleet and main running lines.

Woodland Scenics market a wheel cleaner which is a tray with two strips laid at the appropriate track gauge on which the locomotive stands on. These 'cleaner' strips lie on top of two copper strips that are conductive, and are connected to the power supply so that the locomotive is powered and the wheels rotate against the 'cleaner' strips. In the Woodland version, the strips can be swapped out, depending on what is required to be done.

To assist users Woodland have provided a handy video to show how it should be operated. I have the Gaugemaster equivalent, but this seems to take a long time and it seemed to be polishing the crud-encrusted surface. Having used it on a couple of locos, they did run a bit better, but it was only after the cotton bud and meths were applied that their original vigour was restored. This item (Dec 2014) is currently priced at £34.95.

I have some Portescap-fitted (RG4) locos, for which the electrical Relco track cleaner s are unsuitable, but pre-Portescap, the Relcos did work. I tried Railzip - this is a red glupe that you put a drop of on each rail and then run a loco round to spread it. I have to say the results were inconclusive, and I still found myself rubbing away with the old track cleaning block.

Of track cleaning blocks there are 3: Hornby, Peco and the Double O Gauge Association. The Hornby one is made for a hard, durable material and wasn't terribly effective; the Peco one is effective but leaves a film on the rails (there's also a suggestion that they scratch the surface); whilst the Double O Gauge Association one is OK.

BUT using blocks on modern loco wheels is not good, as they rub the chrome finish off the wheels - particularly on the Hornbys. This is more critical with DCC, where clean wheels and rails are essential. The answer seems to be isopropanol applied with a cloth - the perfumed version is good old surgical spirit.

This is particularly good for loco wheels. I now 'shine' the rails up with the Double O block, and then clean the surfaces with isopropanol to remove the film. But this leaves the problem of cleaning the rails of a large loft layout with the odd tunnel.

Having read the various alternative forums (RMWeb, et al), the conclusion seemed to be a heavy brass tanker car sold in the USA that dispensed isopropanol through a washable pad on the bottom of the car, but this was quite expensive.

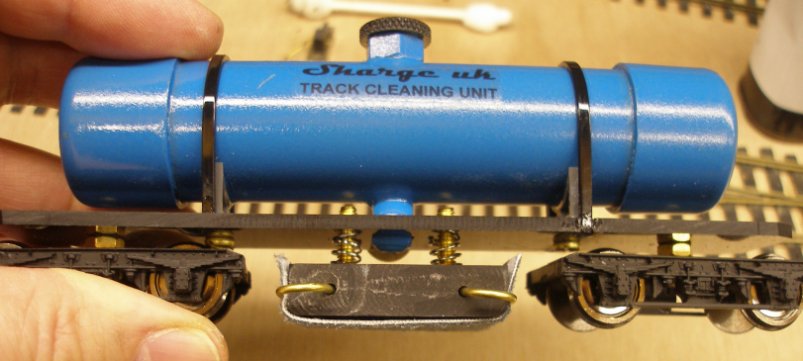

Then in a recent 'Railway Modeller' there was a reference to the Sharge UK offering at £50. As track cleaning is now problematical, I bought one.

This is what you get in the box: the tanker wagon; a syringe, spare pads and a page of instructions. Track cleaning fluid is not included, and there is a list of things that should NOT be used. Interestingly, there only two things which are recommended. So as surgical spirit is not on the banned list, and is generally liked by the fraternity, we went with that.

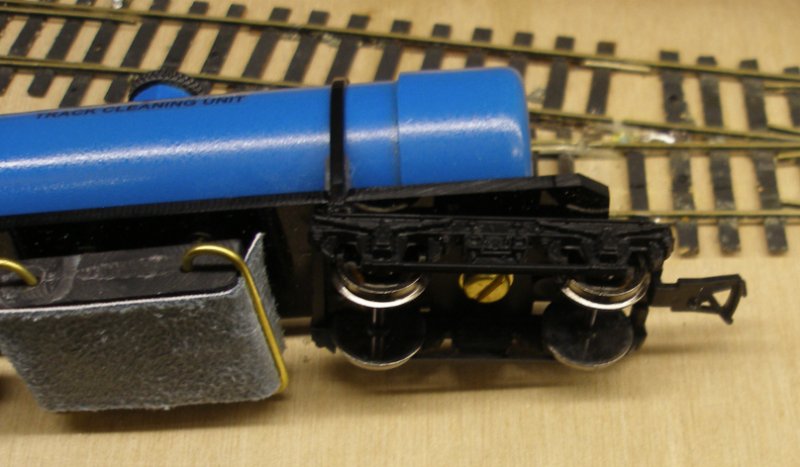

The tank car is mounted on two free-running BR Mark 1 bogies, with good quality metal wheels and modern tension lock couplings. These are permanently fixed to the bogies.

The block is kept firmly on the rails by a set of springs; the weight of the tank ensuring firm engagement.

The instructions recommend that the car is propelled, and despite the appearance that it is being towed, a wrong line running order is in operation whilst the car traverses all our main running lines.

It should come as no surprise that the car works, but here is proof that we started the first run with a clean pad...

This is the state of the pad after using a full load (10Ml) of cleaning fluid and having traversed some 160 foot of trackage.

The instructions do say that the pads should/can be washed frequently.

Initial thoughts were that the car rode well and makes positive contact with the track.

However, within a couple of days the valves became more difficult to work and the cleaning fluid couldn't be controlled, with the tank emptying quickly. Initially I thought this might be an error I was making.

However, I am grateful to Colin Meredith who had similar experiences with the Mark1, and has provided detailed notes regarding the Sharge Mark 2.

Colin notes:

"The Mk1 'Sharge' cleaner suffered problematic flow valve problems which proved its downfall and probably due to poor machining and the tiny 'O' ring seals. Unwisely, or otherwise, I purchased the Mk2 “Sharge” track cleaner and I would add at a greatly inflated cost! The valve operation and flow is improved but it has also been cheapened by being smaller in capacity and having thinner and more flimsy cleaning-pad fixing-clips."

Colin adds: "I have mentioned to several people that IPA (Isopropyl Alcohol) can be diluted 50% - 50% water, shaken well. Many recommend 70% IPA to 30% water which I find is stronger than necessary."

The information for the Mk 2 is as follows:

Tank Base-Plate: 148mm x 24 This is shorter in length, narrower, and lower by approx. 10mm.

Tank: 131mm x 22mm The Mk 2 tank is longer in length but has a smaller diameter of 22mm compared with 26mm of the Mk 1 tank/fluid container.

The Mk 2 bogies are longer, overall, than those fitted to the Mk 1. The height difference is about 10mm when sitting on the track.

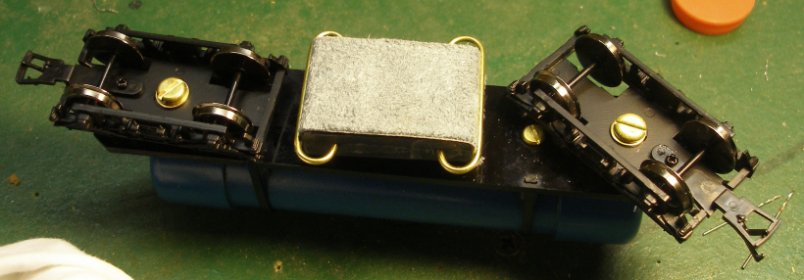

In the images you will see that the Mk 2 cleaner now has the cleaning pad assembly from the Mk 1, the fixing screws being slightly longer on the Mk 1 so were swapped.

It should also be possible to swap the base-plate and bogies although the Mk 1 does have the cut-out for the valve, as you will know, but easy enough to fill-in.

The price increase of approximately £30.00 for the Mk 2 is not, in my opinion, warranted and the cleaner needs to be improved even further.

Whilst searching I find some excellent reviews relating to the Bachmann track cleaner, despite it being based on a USA truck and having "HO" wheels as opposed to "OO”. They are also a great deal cheaper than the over-priced “Sharge” unit and are said to be based more closely on the “CMX” track cleaner which is a USA product. I have two on order at £72.04… Two for the price of one and change with free p+p.

After further tests I also noted that, apart from the cheaper pad fixing clips, the material supplied with the Mk 2 is so thin that I could see daylight through it and it is too thin to fit to the Mk 1 pad and clips. The valves(?) of the Mk 2 are poor and don’t allow a proper control flow."

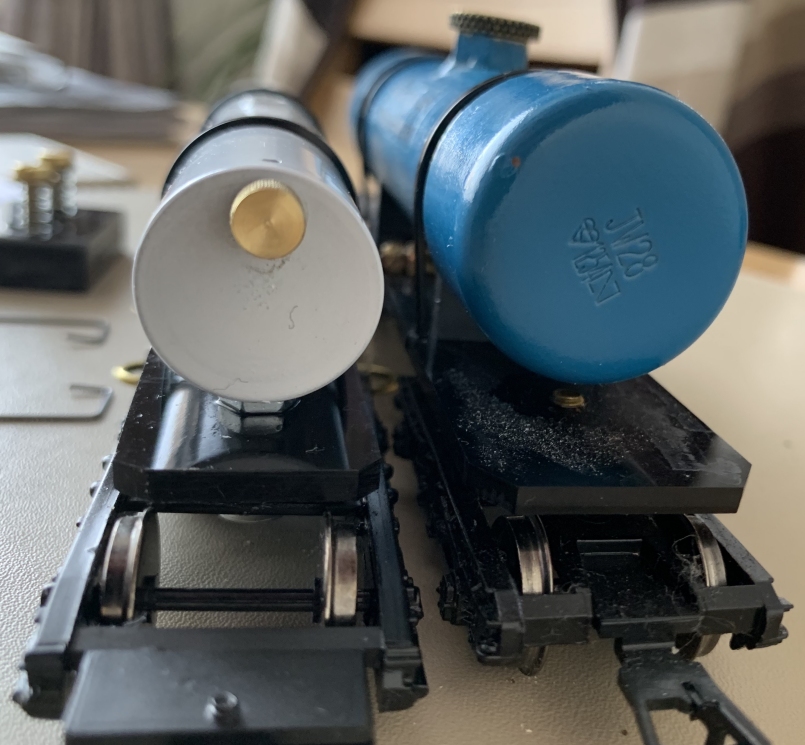

Colin's photo shows the Mark 1 (top) and the Mark 2 (below). As can be seen, the Mark 1 pad and clips have been fitted to the Mark 2 (Esso), with the Mark 2 assembly in the foreground. An early criticism of the Mark 1 was that the elongated clips fowled platform edges, and the square-ended silver Mark 2 type are more compact.

The larger capacity tank of the Mark 1 is clearly illustrated in Colin's end-view shot. I suspect that users of the original tank had loading gauge issues with the filler, exacerbated by the larger tank.

Here is a detailed shot of the revised filler arrangements. The Mark 1 had a chunky screw-in filler cap with a knurled edge. The revised screw-in cap is clearly neater, and as noted, more compact profile, but Colin's photo neatly illustrates how much more fiddly fitting the cap is: not only is it small enough to be easily lost in the scenery when refilling, but also needs a screw driver to fit or remove.The photo below provides a close-up of this feature.

Finally, Jerry Allen has provided a very comprehensive review of this product on YouTube:

This next section is not for those of a delicate nature as it features some rough-an-ready butchery..

Back in the day one Saturday I spent my pocket money on a Triang track cleaner, and it struck me that possibly the whole track cleaning car was being over-complicated.

A visit to eBay found one in poor condition for the princely sum of £6, and also someone makes replacement cleaning pads.

For scale layouts the wheels our 'old school' but a quick upgrade using a set of old MAJ LMS-type allowed testing to start, as per the photos below.

And after a few circuits, here are the results. It is cleaning the track, but the loose weave of the cleaning pads is obviously shedding fibres, as can be seen if the rear pair of axles are examined as the threads have wrapped themselves around them.

.

.

There is clearly potential to improve the pads, and a visit to the local ironmonger is required. A further improvement might be a piece of sponge inserted between the underside of the car and the top of the pad.

The obvious benefit of the Sharge is the tank allowing a decent 'load' to be dispensed, and this was a clear draw back of the original Triang item.

Down at the local ironmongers were a wonderful selection of draft excluders, including this wonderful product which seems to have been designed as a replacement strip for the Triang car. The Kontrol Drip Strip has a smooth, non-fiberous surface, and has sufficient rigidity to provide full contact with the rail surface.

And here is the new rail cleaning train.

This is now a much harder working combination. The Sharge Mark 1 is loaded with IPA (currently neat IPA) and the Triang car follows with a DRY pad.

What is very marked is how much grot the trailing dry pad has picked-up from behind the active Sharge. The pad is also slightly damp, so although the IPA evaporates quickly, not quickly enough not to provide some benefit to the second, dry car. Also noticeable, despite the denser weave of the Dry Strip, there are still some fibres being picked-up on the trailing axle but greatly reduced compared to the replacement pads procured via eBay.

One final note regarding the Sharge Mark 1: it fowls the loading gauge with the top screw cap fitted so now, when being operated, the screw cap travels in one of the compartments in the Triang car. With the roof popped back, the cap is less likely to be lost.

As a post script, something I have not seen before is this Wheel Cleaner installed on the McKinley Railway (www.mckinleyrailway.com). There is a pair of longitudinal pads that take the place of the rail head and are then oscillated forwards and backwards, so that there is a clear rubbing action as each wheel rotates across it. The Lux Modellbau website does not allow direct linking to individual product entries but can be found under the H0 » Radreinigungsanlagen tab. The cost is c. GBP 265.